- Molecular Formula: MoSe2

- CasNo.: 12058-18-3

- Melting point: >1200 °C

- Appearance: crystalline solid

- ProductionCapacity:

- Purity:

- Packing:

-

Product Details:

Reliable Quality Quality Manufacturer Supply 99.9%-99.99% Molybdenum(IV) Selenide 12058-18-3 On Stock

- Molecular Formula:MoSe2

- Molecular Weight:253.86

- Appearance/Colour:crystalline solid

- Melting Point:>1200 °C

- PSA:0.00000

- Density:6 g/cm3

- LogP:-0.53660

MOLYBDENUM SELENIDE(Cas 12058-18-3) Usage

Synthesis

High-quality molybdenum diselenide monolayer?film?was grown directly on the substrates (SiO2/Si) by the chemical vapour deposition (CVD) method.

Application

Having a?direct optical band gap of 1.48 eV with a photoluminescence peak at 840 nm, molybdenum diselenide monolayer?film?is?ideal for applications in optoelectronics. Also, with?with its narrower bandgap, higher optical absorbance and larger spin-splitting energy than MoS2,?MoSe2?ultrathin films?are potentially?better than MoS2 for the applications in tunnel FETs and optoelectronic devices.

Definition

Available as a 40-micron powder.

InChI:InChI=1/Mo.2Se/rMoSe2/c2-1-3

12058-18-3 Relevant articles

Synthesis of MoSe2 nanocrystallites by a solvothermal conversion from MoO3

Zhan,Zhang,Qian,Wang,Xie,Qian

, p. 497 - 501 (1999)

Nanocrystalline 2H-MoSe2 was prepared fr...

MoSe2/CdSe Heterojunction Destruction by Cation Exchange for Photoelectrochemical Immunoassays with a Controlled-Release Strategy

Leng, Dongquan,Zhao, Jihao,Ren, Xiang,Xu, Rui,Liu, Lei,Liu, Xuejing,Li, Yuyang,Wei, Qin

, p. 10712 - 10718 (2021)

Herein, a split-type immunoassay strateg...

Controllable synthesis of flower-like MoSe2 3D microspheres for highly efficient visible-light photocatalytic degradation of nitro-aromatic explosives

Huang, Jingwen,Jin, Bo,Liu, Huiqiang,Li, Xiaojuan,Zhang, Qingchun,Chu, Shijin,Peng, Rufang,Chu, Sheng

, p. 11424 - 11434 (2018)

Nitro-aromatic explosives existing on th...

Structural, optical and microscopic studies of tungsten substituted molybdenum diselenide thin films

Sathe,Hankare,Manikshete,Chate,Patil

, p. 187 - 193 (2010)

A modified chemical bath deposition meth...

Cr1.45Tl1.87Mo15Se19, a monoclinic variant of the hexa-gonal In3Mo15Se 19 type

Gougeon,Salloum,Potel

, p. i87-i90 (2009)

The monoclinic compound Cr1.45Tl1.87Mo 1...

Kinetics and Diffusing Species in the Reaction between Molybdenum and Selenium Vapor

Sasaki, Yoshinori,Wakatsuki, Noboru

, p. 863 - 864 (1993)

Metallic molybdenum was selenidized at t...

Modulating in-plane electron density of molybdenum diselenide via spontaneously atomic-scale palladium doping enables high performance lithium oxygen batteries

He, Miao,Hu, Anjun,Li, Jiabao,Li, Minglu,Long, Jianping,Shu, Chaozhu,Yan, Yu

, (2021)

Lithium-oxygen batteries (LOBs) are cons...

Preparation of MoSe2 nano-islands array embedded in a TiO2 matrix for photo-regulated resistive switching memory

Han, Pengde,Sun, Bai,Cheng, Sen,Yu, Fangli,Jiao, Baoxiang,Wu, Qisheng

, p. 619 - 625 (2016)

The electrically driven resistance chang...

Synthesis and characterization of indium intercalation compounds of molybdenum sulphoselenide

Mandal,Srivastava

, p. 3191 - 3196 (1996)

The synthesis, structure and properties ...

Dual surfactants applied in synthesis of MoSe2 for high-efficiency hydrogen evolution reaction

Li, Changdian,Zhu, Lili,Li, Han,Li, Hui,Wu, Ziqiang,Liang, Changhao,Zhu, Xuebin,Sun, Yuping

, (2021)

Molybdenum diselenide (MoSe2) has been c...

Cu Insertion into the Mo12 Cluster Compound Cs2Mo12Se14: Synthesis, Crystal and Electronic Structures, and Physical Properties

Al Rahal Al Orabi, Rabih,Fontaine, Bruno,Gautier, Regis,Gougeon, Patrick,Gall, Philippe,Bouyrie, Yohan,Dauscher, Anne,Candolfi, Christophe,Lenoir, Bertrand

, p. 6616 - 6624 (2016)

Mo-based cluster compounds are promising...

Hierarchical Co0.85Se-CdSe/MoSe2/CdSe Sandwich-Like Heterostructured Cages for Efficient Photocatalytic CO2 Reduction

Du, Lizhi,Chen, Yajie,Wang, Qi,Zhao, Yumeng,Li, Longge,Liu, Xiu,Tian, Guohui

, (2021)

Fabricating efficient photocatalysts wit...

Formation and interlayer decoupling of colloidal MoSe2 nanoflowers

Sun, Du,Feng, Simin,Terrones, Mauricio,Schaak, Raymond E.

, p. 3167 - 3175 (2015)

We report the colloidal synthesis of sub...

Superconducting properties of solid solutions (Mo6Se8)Pbx and PbxMo6Se8 in the ternary system Pb-Mo-Se

Corrignan, Anita,Hamard, Christelle,Pena, Octavio

, p. 260 - 264 (1999)

The homogeneity regions of the supercond...

Syntheses and Structural, Physical, and Theoretical Studies of the Novel Isostructural Mo9 Cluster Compounds Ag2.6CsMo 9Se11, Ag4.1ClMo9Se11, and h-Mo9Se11 with Tunnel Structures

Gougeon, Patrick,Potel, Michel,Gautier, Regis

, p. 1257 - 1263 (2004)

The new isostructural compounds Ag2.6CsM...

Synergetic effect of TiO2 as co-catalyst for enhanced visible light photocatalytic reduction of Cr(VI) on MoSe2

Chu, Haipeng,Lei, Wenyan,Liu, Xinjuan,Li, Jinliang,Zheng, Wei,Zhu, Guang,Li, Can,Pan, Likun,Sun, Changqing

, p. 19 - 25 (2016)

MoSe2-TiO2 composites were successfully ...

Influence of S and Te substitutions on the thermoelectric properties of the cluster compound Ag3.8Mo9Se11

Masschelein,Candolfi,Dauscher,Gendarme,Rabih, Al Rahal Al Orabi,Gougeon,Potel,Gall,Gautier,Lenoir

, p. 360 - 367 (2018)

We report on a detailed study of the inf...

Graphene-like 2H/1T-MoSe2 with superior full spectrum absorption: Morphology and phase engineering

Wu, Jinzhu,Liu, Yue,Yao, Yuan,Shao, Yanbin,Wu, Xiaohong

, (2021)

Superabsorbers can find application in t...

Phase Transition and Superconductivity Enhancement in Se-Substituted MoTe2 Thin Films

Li, Peiling,Cui, Jian,Zhou, Jiadong,Guo, Dong,Zhao, Zhenzheng,Yi, Jian,Fan, Jie,Ji, Zhongqing,Jing, Xiunian,Qu, Fanming,Yang, Changli,Lu, Li,Lin, Junhao,Liu, Zheng,Liu, Guangtong

, (2019)

Consecutively tailoring few-layer transi...

Non-stoichiometry and structure of molybdenum diselenide

Naruke,Wakatsuki,Hoshi,Sasaki

, p. 647 - 655 (1996)

Molybdenum diselenides were synthesized ...

Photoelectrochemical reduction of N2to NH3under ambient conditions through hierarchical MoSe2@g-C3N4heterojunctions

Mushtaq, Muhammad Asim,Arif, Muhammad,Fang, Xiaoyu,Yasin, Ghulam,Ye, Wen,Basharat, Majid,Zhou, Bo,Yang, Shiyu,Ji, Shengfu,Yan, Dongpeng

, p. 2742 - 2753 (2021)

Ammonia is the main precursor for the pr...

Chevrel-phase solid solution Mo6Se8-xTex. Study of its superconducting, magnetic and NMR properties

Hamard,Auffret,Pena,Le Floch,Nowak,Wojakowski

, p. 339 - 349 (2000)

The Chevrel-phase solid solution Mo6Se8-...

Synthesis, Crystal Structure, and Transport Properties of the Hexagonal Mo9 Cluster Compound Ag3RbMo9Se11

Gougeon, Patrick,Gall, Philippe,Merdrignac-Conanec, Odile,Aranda, Lionel,Dauscher, Anne,Candolfi, Christophe,Lenoir, Bertrand

, p. 9684 - 9692 (2017)

Mo-based cluster compounds are promising...

Single-Crystal Studies of the Chevrel-Phase Superconductor LaxMo6Se8: I: Correlation betweenTcand the Interatomic Distances

Le Berre,Pena,Perrin,Sergent,Horyn,Wojakowski

, p. 151 - 159 (1998)

We report, for the first time in the lit...

Two-dimensional graphene-like MoSe2 nanosheets anchored on hollow carbon nanofibers as a cathode catalyst for rechargeable Li-O2 batteries

Lai, Yanqing,Chen, Wei,Zhang, Zhian,Gan, Yongqing,Yang, Xing,Li, Jie

, p. 19843 - 19847 (2016)

MoSe2@HCNF hybrids are synthesized via a...

A novel route to obtain molybdenum dichalcogenides by hydrothermal reaction

Fan, Rong,Chen, Xianhui,Chen, Zuyao

, p. 920 - 921 (2000)

Hydrothermal reactions between aqueous N...

Ag2.54Tl2Mo12Se15: A new structure type containing Mo6 and Mo9 clusters

Gougeon,Gall,Gautier,Potel

, p. i67-i70 (2010)

The novel structure-type Ag2.54Tl2Mo 12S...

Crystal data for mixed-anion molybdenum dichalcogenides

Schneemeyer, Lynn F.,Sienko

, p. 789 - 791 (1980)

-

CoSe2/MoSe2 Heterostructures with Enriched Water Adsorption/Dissociation Sites towards Enhanced Alkaline Hydrogen Evolution Reaction

Zhao, Guoqiang,Li, Peng,Rui, Kun,Chen, Yaping,Dou, Shi Xue,Sun, Wenping

, p. 11158 - 11165 (2018)

Transition-metal dichalcogenides (TMDs) ...

Optimization of MoSe2 nanostructure by surface modification using conducting polymer for degradation of cationic and anionic dye: Photocatalysis mechanism, reaction kinetics and intermediate product study

Mittal, Honey,Khanuja, Manika

, (2020)

In the present work, optimum nanocomposi...

Synthesis and characterization of indium intercalation compounds of molybdenum diselenide, InxMoSe2 (0 ≤ x ≤ 1)

Srivastava,Avasthi

, p. 1919 - 1924 (1989)

The synthesis, structure and properties ...

One-pot hydrothermal synthesis and selective etching method of a porous MoSe2 sand rose-like structure for electrocatalytic hydrogen evolution reaction

Tran, Xuan Thai,Poorahong, Sujittra,Siaj, Mohamed

, p. 52345 - 52351 (2017)

The development of a platinum-free elect...

In-situ transformation into MoSe2/MoO3 heterogeneous nanostructures with enhanced electrochemical performance as anode material for sodium ion battery

Kang, Wenpei,Wang, Yuyu,Cao, Dongwei,Kang, Zixi,Sun, Daofeng

, p. 410 - 418 (2018)

As anode materials, the electrochemical ...

X-ray characterization, electronic band structure, and thermoelectric properties of the cluster compound Ag2Tl2Mo9Se11

Al Rahal Al Orabi, Rabih,Gougeon, Patrick,Gall, Philippe,Fontaine, Bruno,Gautier, Rgis,Colin, Malika,Candolfi, Christophe,Dauscher, Anne,Hejtmanek, Jiri,Malaman, Bernard,Lenoir, Bertrand

, p. 11699 - 11709 (2014)

We report on a detailed investigation of...

1T-2H MoSe2 modified MAPbI3 for effective photocatalytic hydrogen evolution

Cai, Yifei,Chen, Jinxi,Lou, Yongbing,Zhang, Tiantian

, (2021/10/25)

Organic-inorganic perovskites such as io...

Microwave hydrothermal synthesis of hierarchical Ce-doped MoSe2@CNTs as an efficient non-precious catalyst for hydrogen evolution in both acidic and alkaline media

Chen, Zhidong,Ji, Dingwei,Liu, Changhai,Luo, Linlin,Wang, Wenchang,Yao, Yanhua

, (2021/11/16)

To enhance the intrinsic activity and th...

Synthesis, Structure, and Spectroscopic Study of Redox-Active Heterometallic Cluster-Based Complexes [Re5MoSe8(CN)6]n

Cordier, Stéphane,Dorcet, Vincent,Loginov, Ivan P.,Muravieva, Viktoria K.,Nadolinny, Vladimir A.,Naumov, Nikolay G.,Ryzhikov, Maxim R.,Sukhikh, Taisiya S.,Yanshole, Vadim V.

, p. 8838 - 8850 (2021/06/27)

The heterometallic cluster-based compoun...

12058-18-3 Process route

-

- 7782-49-2

selenium

-

- 7439-98-7

molybdenum

-

- 12058-18-3

molybdenum selenide

ConditionsConditions Yield at 800,900,1000 and 1150°C;Kinetics;In neat (no solvent); slow heating of weighed mixt. (sealed evacuated quartz ampoule, ca. 1E-5 Torr) to 950°C (horizontal furnace), maintaining there for 1 week; powder X-ray diffraction;sheet of molybdenum and an excess of selenium shots placed at ends of a silica tube, tube sealed under vac., selenidization at 773-873 K (selenium vapor at 1.33 kPa); Kinetics;In neat (no solvent); Mo and Se powder weighed accurately, placed in a quartz tube, vacuum sealed, initial react. at 750 ° C over 40 h,, resulted powder mechanical shaking, final react. at 1000 ° C over 40 h, slow cooling to 25 ° C;In neat (no solvent); heating (sealed quartz ampoule, 873 K); X-ray diffraction;In neat (no solvent); reacting Se vapor with powdered metal at 1000K in a flowing inert gas orby reacting the components in evacuated quartz ampules, utilizing a particle size of less than 50 μm; x-ray diffraction;at 800,900,1000 and 1150°C;In neat (no solvent); Mo powder and Se shot were mixed, sealed in a quartz ampoule, and heated at 600°C for 3 d, after remixing, the sample was homogenized by heating at 1000°C for further 4 d;;stoichiometric mixtures of elements were sealed in evacuated silica tubes; heated to 450°C for two days; fired at 1000°C for 10 days;With Te; In neat (no solvent); Mo and Te thin films sequentially deposited on a polished glass substrate, annealing under Se and Te pressure at 770 K, 24 h; crystallized stoich. film;In neat (no solvent); formation of MoSe2 in an evacuated quartz capsule;; elem. anal. given; X-ray diffraction;;In neat (no solvent, solid phase); stoich. proportion; evacuated; sealed (1E-5 torr); mixed; slowly heatedto 800°C (40°/h); after 72 h cooled; heated at 1040°C (168 h); ESCA;stoichiometric amounts of elements heated in a degassed, sealed, evacuated silica tube upto 900°C over a period of 5 days and kept at this temp. for 1 week; cooled to room temp. then reheated to 900°C for another week;In neat (no solvent); heating (dual-chamber quartz tube, full consumption of Se vapors);In neat (no solvent, solid phase); at 850°C for 3 d in quartz tube;mixt. grinding (agate mortar), heating in evac. sealed (under Ar) quartztube at 1273+/-5 K for 24 h, cooling at room temp.; SEM;In neat (no solvent); Mo powder reduction in H2 stream (850°C, 4 h), direct synthesis;In neat (no solvent); (vac.), heating (400°C, 2 d), heating (750°C, 48 h), heating (1000°C, 40 h), slow cooling;In neat (no solvent); react. Se with Mo (2:1) in evacuated (ca. 1E-2 Pa Ar) silica tube heatedat 700°C for 2 days;In neat (no solvent); multilayer deposition of vapors of Mo (from electron gun source) and Se (from Knudsen cell) onto Si-wafer at 5E-6 Torr, annealing at 550 K; 30-53% Mo in deposit, varying layer thickness; powder X-ray diffraction; Kinetics;In neat (no solvent); (Ar), glove-box; stoich. mixt. heated in evacuated silica tubes for ca. 2 d;In neat (no solvent, solid phase); heating of stoich. mixt. of elements in sealed evacuated silica tubes for 2 d at 1073 K;With dicopper(I) triselenostannate(IV); In neat (no solvent); at 550 ℃; Reagent/catalyst; Inert atmosphere;at 800 ℃; for 48h;at 699.84 ℃; for 48h; under 7.50075E-05 Torr; Sealed tube; Inert atmosphere;at 699.84 ℃; for 48h;In neat (no solvent, solid phase); at 799.84 ℃; for 12h; Sealed tube;at 600 ℃; for 48h; Sealed tube;at 600 ℃; for 48h; Sealed tube;-

- 7782-49-2

selenium

-

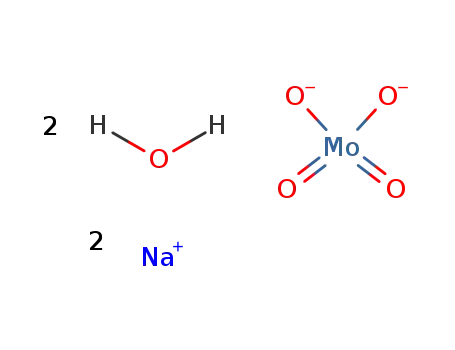

- 7631-95-0

sodium molybdate dihydrate

-

- 12058-18-3

molybdenum selenide

ConditionsConditions Yield With sodium tetrahydroborate; In water; at 200 ℃; for 12h; Autoclave;With hydrazine hydrate; sodium hydroxide; In water; at 180 ℃; for 48h; pH=12; Autoclave; High pressure;selenium; With hydrazine hydrate; for 1h;sodium molybdate dihydrate; In N,N-dimethyl-formamide; at 200 ℃; for 24h; Autoclave; High pressure;at 500 ℃; for 4h; Inert atmosphere;With sodium tetrahydroborate; In ethanol; water; at 200 ℃; for 48h; Autoclave;selenium; sodium molybdate dihydrate; With sodium tetrahydroborate; ethanol; In water; for 0.0833333h;In water; at 200 ℃; for 48h; Autoclave;at 450 ℃; for 3h; Inert atmosphere; Calcination;selenium; sodium molybdate dihydrate; With sodium tetrahydroborate; In water; at 20 ℃; for 0.833333h;In water; at 180 ℃; for 12h; Autoclave;selenium; With hydrazine hydrate; at 20 ℃; for 0.5h;sodium molybdate dihydrate; With sodium tetrahydroborate; In ethanol; water; for 0.5h;In ethanol; water; at 180 ℃; for 48h; Autoclave;12058-18-3 Upstream products

-

7782-49-2

selenium

-

7439-98-7

molybdenum

-

7631-95-0

sodium molybdate dihydrate

-

7446-08-4

selenium(IV) oxide